Abstract

A partial nitritation/anammox (PN/A) process was operated at two different mixing intensities to quantify the extent to which diffusional limitations impact process rates. At a steady-state operation, the total inorganic nitrogen removal efficiency in the bench-scale sequencing batch reactors was found to increase as mixing intensity decreased (62 and 84% for average velocity gradient (G) values of 15 and 5.3 s−1, respectively). The half-velocity constants  with respect to bulk-phase dissolved oxygen (DO) concentration for ammonia-oxidizing bacteria (AOB) and anaerobic ammonium-oxidizing (anammox) organisms were estimated on the basis of nitrogen removal rates that were observed in activity tests. The activity tests were conducted over a range of bulk-phase DO concentrations. The best-fit

with respect to bulk-phase dissolved oxygen (DO) concentration for ammonia-oxidizing bacteria (AOB) and anaerobic ammonium-oxidizing (anammox) organisms were estimated on the basis of nitrogen removal rates that were observed in activity tests. The activity tests were conducted over a range of bulk-phase DO concentrations. The best-fit  values were estimated to be 0.68 ± 0.34 and 0.54 ± 0.56 mg O2/L for G values of 15 and 5.3 s−1, respectively. The AOB values were not statistically different (p = 0.19) between mixing conditions which were consistent with AOB dominating the surface of granules. The best-fit

values were estimated to be 0.68 ± 0.34 and 0.54 ± 0.56 mg O2/L for G values of 15 and 5.3 s−1, respectively. The AOB values were not statistically different (p = 0.19) between mixing conditions which were consistent with AOB dominating the surface of granules. The best-fit  values were estimated to be 0.13 ± 0.09 and 0.55 ± 0.40 mg O2/L for G values of 15 and 5.3 s−1, respectively, and were statistically different

values were estimated to be 0.13 ± 0.09 and 0.55 ± 0.40 mg O2/L for G values of 15 and 5.3 s−1, respectively, and were statistically different  . The results demonstrated that mixing conditions should be considered when designing PN/A processes and provide quantitative results that can be employed to improve models of these processes.

. The results demonstrated that mixing conditions should be considered when designing PN/A processes and provide quantitative results that can be employed to improve models of these processes.

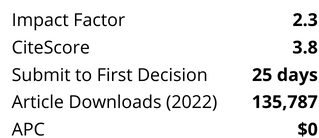

This article has been made Open Access thanks to the kind support of CAWQ/ACQE (https://www.cawq.ca).

INTRODUCTION

There is a growing interest in the use of short-cut nitrogen removal processes that remove nitrogen from wastewater streams with fewer resources (energy and carbon) than traditional technologies (Kartal et al. 2010). Lackner et al. (2014) reported 100 full-scale installations of technologies that employ partial nitritation and anammox (PN/A) for nitrogen removal. PN/A processes oxidize a portion of ammonia to nitrite with ammonia-oxidizing bacteria (AOB) in the presence of dissolved oxygen (DO), while ammonium and nitrite are removed by anammox bacteria in zones where DO is depleted (Van Hulle et al. 2010). The successful operation of PN/A processes typically depends on establishing conditions (including low DO concentrations) that result in the wash-out of nitrite-oxidizing bacteria (NOB) from the process. The DO profile is critical to successful operations and is typically controlled by setting the duration of aerated and unaerated periods and the target DO concentration while aerating (Lackner et al. 2015).

The successful operation of PN/A processes typically requires the implementation of sophisticated pH and DO control on aeration (Wett 2007; Wett et al. 2007). There is, however, a lack of consensus with regard to the target DO concentration that should be employed during aeration. Lackner et al. (2014) reported target DO concentrations that ranged from 0.3 to 1.5 mg O2/L. The matter is further complicated by the fact that some technologies utilize intermittent aeration, while others utilize continuous aeration (Lackner et al. 2014; Corbalá-Robles et al. 2016).

Process modeling can be employed to inform decisions regarding process operation and control. Mechanistic models employ switching functions which incorporate half-velocity constants  to describe the impact of DO concentration on the growth of AOB, NOB, and anammox organisms (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016). Historically, the models have assumed that all organisms are directly exposed to the bulk liquid substrate concentrations, and the half-velocity coefficients (referred to as intrinsic) have been considered to be constant. However, recent studies have shown that the values of substrate half-velocity constants should be considered as variables (Arnaldos et al. 2015; Ma et al. 2016) with values having substantial ranges (i.e. 33-fold variation of reported

to describe the impact of DO concentration on the growth of AOB, NOB, and anammox organisms (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016). Historically, the models have assumed that all organisms are directly exposed to the bulk liquid substrate concentrations, and the half-velocity coefficients (referred to as intrinsic) have been considered to be constant. However, recent studies have shown that the values of substrate half-velocity constants should be considered as variables (Arnaldos et al. 2015; Ma et al. 2016) with values having substantial ranges (i.e. 33-fold variation of reported  values for AOB). Limitations in oxygen availability in the interior of floc and granules that are imposed by advection and diffusion have been hypothesized to be responsible for differences in half-velocity constants. The observed values should be considered as extant (Arnaldos et al. 2015). While floc-based models that incorporate diffusional resistances have been developed, they are difficult to apply due to the uncertainty in many variables (Shaw et al. 2015). There is a need to have information that describes how extant half-velocity values vary as a function of factors that impact upon diffusive processes.

values for AOB). Limitations in oxygen availability in the interior of floc and granules that are imposed by advection and diffusion have been hypothesized to be responsible for differences in half-velocity constants. The observed values should be considered as extant (Arnaldos et al. 2015). While floc-based models that incorporate diffusional resistances have been developed, they are difficult to apply due to the uncertainty in many variables (Shaw et al. 2015). There is a need to have information that describes how extant half-velocity values vary as a function of factors that impact upon diffusive processes.

Previous studies have focused on factors that influenced diffusive limitations in systems that included AOB and NOB. Mixing intensity has been reported to influence both advection and diffusion in floc. Chu et al. (2003) reported that  values increased as mixing intensity decreased when activated sludge was tested in a respirometer. Furthermore, Wu et al. (2017) found that

values increased as mixing intensity decreased when activated sludge was tested in a respirometer. Furthermore, Wu et al. (2017) found that  values increased with increased floc size and nitrifier density inside flocs. While these studies demonstrate the impact of mixing intensity on

values increased with increased floc size and nitrifier density inside flocs. While these studies demonstrate the impact of mixing intensity on  , there is less information on PN/A granules that rely on organisms with opposing DO sensitivities and which are operated to optimize DO gradients within the granules.

, there is less information on PN/A granules that rely on organisms with opposing DO sensitivities and which are operated to optimize DO gradients within the granules.

This study focused on the impact of mixing intensity on the observed extant half-velocity constants of AOB  and anammox bacteria

and anammox bacteria  values in a PN/A process environment. It was hypothesized that the AOB activity would increase with mixing intensity since it would depend on the availability of both

values in a PN/A process environment. It was hypothesized that the AOB activity would increase with mixing intensity since it would depend on the availability of both  and oxygen to the organisms, and both of these would increase with improved mass transfer. By contrast, the anammox activity is reduced in the presence of DO and, therefore, may increase under conditions of reduced mass transfer.

and oxygen to the organisms, and both of these would increase with improved mass transfer. By contrast, the anammox activity is reduced in the presence of DO and, therefore, may increase under conditions of reduced mass transfer.  values were estimated by modeling data that were generated in a PN/A reactor when it was operated in a batch mode. The batch tests facilitated the calculation of substrate utilization rates for ammonium, nitrite, and nitrate under different DO concentrations. The estimated

values were estimated by modeling data that were generated in a PN/A reactor when it was operated in a batch mode. The batch tests facilitated the calculation of substrate utilization rates for ammonium, nitrite, and nitrate under different DO concentrations. The estimated  values provide wastewater treatment practitioners with insights into the impact of mixing intensity on process rates and ultimately with establishing target bulk liquid DO concentrations when aerating PN/A reactors.

values provide wastewater treatment practitioners with insights into the impact of mixing intensity on process rates and ultimately with establishing target bulk liquid DO concentrations when aerating PN/A reactors.

METHODOLOGY

Experimental plan

A bench-scale sequencing batch reactor (SBR) was operated to generate data that were subsequently employed to assess the impact of mixing intensity on the rates of substrate utilization. It was operated for an extended period of time at two different mixing intensities to facilitate an assessment of the impact of mixing intensity on the performance of the reactor and the  and

and  values. In the initial phase of testing, the mixer was operated at 150 rpm (an equivalent of the average velocity gradient

values. In the initial phase of testing, the mixer was operated at 150 rpm (an equivalent of the average velocity gradient  of 15 s−1); while in the second phase of testing, a rotational velocity of 75 rpm (an equivalent

of 15 s−1); while in the second phase of testing, a rotational velocity of 75 rpm (an equivalent  of 5.3 s−1) was employed to span a range of values. After steady-state conditions were established at each mixing intensity, the operational mode of the SBR was switched to the batch mode to conduct a series of activity tests that generated data which was employed to estimate

of 5.3 s−1) was employed to span a range of values. After steady-state conditions were established at each mixing intensity, the operational mode of the SBR was switched to the batch mode to conduct a series of activity tests that generated data which was employed to estimate  and

and  values. The activity tests incorporated anoxic and aerobic conditions as are described in detail subsequently.

values. The activity tests incorporated anoxic and aerobic conditions as are described in detail subsequently.

The goal was to conduct activity tests with the granule morphology that was established through the long-term operation at each mixing intensity. Given the considerable period of time required to complete each phase, resource limitations resulted in the testing of two mixing conditions that spanned a range of intensities. The results of the study facilitated an assessment of which half-velocity parameters were sensitive to mixing intensity. Additional research would be required to develop quantitative relationships between mixing intensity and half-velocity constant values.

Test apparatus

The SBR had an effective volume of 8.0 L, was heated to maintain a temperature of 35 °C, and received diffused air (Bubble Mist, Woodbridge, ON, Canada) provided by an air pump (Elite Optima, Model #A-807, Rolf C. Hagen Inc., Baie d'Urfé, QC, Canada). The reactor was mixed with a 120 mm diameter vertical-flat-blade impeller. The SBR was operated at a hydraulic retention time (HRT) of 12 h with two cycles per HRT. Each cycle consisted of the initial 330 min of continuous feeding (13 mL/min), aerating, and mixing, and this was followed by 20 min of settling and 10 min of decanting. DEMON® biomass from the York River Treatment Plant located in Seaford, VA, USA was used as the inoculum to initiate the SBR operations.

The SBR aeration was controlled using a commercial software (LabVIEW) integrated with a data acquisition module (National Instrument DAQ USB Device, NI USB-6001, National Instruments Corporation, Austin, TX, USA). The pH (Orion™ pH probe, Catalog #9107BN, Thermo Fisher Scientific, Sunnyvale, CA, USA) and DO (Hach LDO® probe, Product #5790000, Hach Company, Loveland, CO, USA) of the SBR contents were continuously monitored and reported to the data acquisition module. The DO probe was calibrated regularly using the air method that was recommended by the operator manual. The aeration control algorithm is subsequently described.

The SBR was fed with a synthetic centrate to maintain a constant influent composition throughout the study. The centrate (Table 1) included ammonium (nitrogen source), bicarbonate (inorganic carbon source), and trace elements as described in previous studies (van de Graaf et al. 1996; Li et al. 2011; Yu et al. 2014) that were dissolved in deionized water. The detailed composition of the trace elements is presented in the Supplementary Materials.

Composition of synthetic centrate

| Component . | Concentration . |

|---|---|

| 2,820 mg/L (500 mg/L as N) |

| 420 mg/L (250 mg/L as CaCO3) |

| 27.2 mg/L |

| 147 mg/L |

| 180 mg/L |

| Trace element I | 1 mL/L of synthetic centrate |

| Trace element II | 1 mL/L of synthetic centrate |

| Component . | Concentration . |

|---|---|

| 2,820 mg/L (500 mg/L as N) |

| 420 mg/L (250 mg/L as CaCO3) |

| 27.2 mg/L |

| 147 mg/L |

| 180 mg/L |

| Trace element I | 1 mL/L of synthetic centrate |

| Trace element II | 1 mL/L of synthetic centrate |

SBR operations

The SBR aeration strategy was adopted from literature reports (Wett 2006; Wett et al. 2007; Jardin & Hennerkes 2012) and employed continuous monitoring of pH and DO to inform a control algorithm that was designed to achieve the PN/A activity. The air-flow settings were adjusted at the outset of the testing, such that the controller could maintain DO in the target range without significant fluctuations. During feeding and mixing, the SBR was intermittently aerated at a flow rate of 5.5–6.5 L/min (Wett et al. 1998) on and off for periods of 6 and 3 min, respectively. Aeration was paused either when the DO exceeded 0.80 mg O2/L or the pH decreased below 7.0. In situations when the pH became less than 7.0, the aeration resumed upon the commencement of the subsequent aeration period when the pH increased above 7.0.

Selective wasting of biomass was employed to minimize the NOB population in the SBR. The selective wasting procedure (Wett et al. 2010, 2013, 2015) involved transferring 300 mL of wasted mixed liquor suspended solids (MLSS) (collected at the end of each SBR cycle) to a separatory funnel, swirling the funnel for 15 s, and then allowing the solids to settle. As the supernatant became clear, the stopcock was opened and granular biomass was collected from the stem at the bottom. The stopcock was closed when the solids surface level reached approximately 66% of the solids blanket depth. These solids were returned to the reactor, while the remaining biomass that was more flocculent in nature was wasted. In this way, the solids retention time (SRT) for low-density floc and high-density granules were decoupled.

The range of SRT for the flocs and granules was estimated on the basis of two different assumptions regarding the separation of the floc and granules in the separatory funnel. One scenario assumed that the selective wasting method achieved no biomass separation and the SRTs for the floc and granules were the same, with a value of 22.5 days. The alternate scenario assumed that the selective wasting method achieved perfect separation where all granules were recycled and at the same time all flocs were wasted. In this scenario, the floc SRT was 6.7 d and the granule SRT approached infinitely. It is believed that the actual SRT values were between the extremes.

Batch activity tests

The batch activity tests were conducted upon the completion of an SBR feeding and mixing cycle and employed procedures that have been previously reported (Tsushima et al. 2007; Williams et al. 2012; Nifong et al. 2013). Each test involved an initial anoxic phase with a 1 h duration where granular  (an equivalent of 50 mg N L−1) and

(an equivalent of 50 mg N L−1) and  (an equivalent of 75 mg N L−1) were added to the reactor and the DO concentration was maintained below detection limits (0.07 mg/L). These dosages were expected to saturate the relevant substrate switching functions based on half-velocity values that were obtained from the literature (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016).

(an equivalent of 75 mg N L−1) were added to the reactor and the DO concentration was maintained below detection limits (0.07 mg/L). These dosages were expected to saturate the relevant substrate switching functions based on half-velocity values that were obtained from the literature (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016).

Upon the completion of the anoxic phase, aerobic conditions were established at targeted DO concentrations, and granular  (an equivalent of 200 mg N L−1) was added to the SBR and the test continued for an hour. The aerobic tests were conducted at different DO concentrations that ranged from 0.25 to 6.42 mg O2/L at

(an equivalent of 200 mg N L−1) was added to the SBR and the test continued for an hour. The aerobic tests were conducted at different DO concentrations that ranged from 0.25 to 6.42 mg O2/L at  and 0.39 to 5.84 mg O2/L at

and 0.39 to 5.84 mg O2/L at  . A total of nine tests at

. A total of nine tests at  and six tests at

and six tests at  were conducted, and the tests with target DO concentrations of 4.0 and 6.0 mg O2/L were replicated twice at

were conducted, and the tests with target DO concentrations of 4.0 and 6.0 mg O2/L were replicated twice at  . Typically, five to six samples were collected over the 1-h duration of both the anoxic and aerobic activity phases to measure

. Typically, five to six samples were collected over the 1-h duration of both the anoxic and aerobic activity phases to measure  ,

,  , and

, and  concentrations. The sampling frequency was increased for the first 15 min of the tests (0, 7.5, and 15 min) when responses were expected to be more rapid and was then reduced to 15-min intervals for the remainder of the test. At the end of the aerobic phase, the reactor contents were analyzed for total suspended solids (TSSs) and volatile suspended solids (VSSs) to establish the MLSS.

concentrations. The sampling frequency was increased for the first 15 min of the tests (0, 7.5, and 15 min) when responses were expected to be more rapid and was then reduced to 15-min intervals for the remainder of the test. At the end of the aerobic phase, the reactor contents were analyzed for total suspended solids (TSSs) and volatile suspended solids (VSSs) to establish the MLSS.

Analytical methods

The concentrations of TSSs, VSSs,  ,

,  , and

, and  were measured according to Standard Methods (American Public Health Association 2005). Ammonium

were measured according to Standard Methods (American Public Health Association 2005). Ammonium  concentrations were measured by an ion-selective electrode (ISE) (Orion™ High Performance Ammonia ISE, 9512HPBNWP, Thermo Fisher Scientific, Sunnyvale, CA, USA). Nitrite

concentrations were measured by an ion-selective electrode (ISE) (Orion™ High Performance Ammonia ISE, 9512HPBNWP, Thermo Fisher Scientific, Sunnyvale, CA, USA). Nitrite  and nitrate

and nitrate  were measured by ion chromatography (Dionex IonPac™ AS4A-SC, Thermo Fisher Scientific, Sunnyvale, CA, USA).

were measured by ion chromatography (Dionex IonPac™ AS4A-SC, Thermo Fisher Scientific, Sunnyvale, CA, USA).

Statistical methods

Multi-response regression was used to calibrate the DO half-velocity constants in the bioprocess model (Ni et al. 2014) that was adopted in this study. Two-sample t-tests (significance level of 0.05) were used to determine whether the DO half-velocity constants differed between the two mixing intensities.

RESULTS AND DISCUSSION

The testing was divided into two phases where the mixer was operated at different speeds and mixing intensities ( and

and  , respectively). Achieving steady state with respect to the activity of the biomass in the reactor was deemed to be important in terms of increasing the accuracy of the subsequent batch activity testing and the confidence in the estimation of the

, respectively). Achieving steady state with respect to the activity of the biomass in the reactor was deemed to be important in terms of increasing the accuracy of the subsequent batch activity testing and the confidence in the estimation of the  . The SBR was therefore operated until steady state was achieved prior to the batch activity tests. Steady-state conditions were assessed based on the presence of stable effluent concentrations of

. The SBR was therefore operated until steady state was achieved prior to the batch activity tests. Steady-state conditions were assessed based on the presence of stable effluent concentrations of  ,

,  , and

, and  over time (Figure 1). Steady state was deemed to be achieved for days 81–165 and 199–228 in Phases 1 and 2, respectively. The average (±std dev) MLVSS concentrations at steady state were 1.2 ± 0.35 and 1.9 ± 0.09 g/L in Phases 1 and 2, respectively.

over time (Figure 1). Steady state was deemed to be achieved for days 81–165 and 199–228 in Phases 1 and 2, respectively. The average (±std dev) MLVSS concentrations at steady state were 1.2 ± 0.35 and 1.9 ± 0.09 g/L in Phases 1 and 2, respectively.

SBR effluent concentrations of nitrogen species and TIN removal versus time.

Comparing Phases 1 and 2, the average effluent  concentration in Phase 2 decreased to approximately 33% of that observed in Phase 1. The effluent concentrations of

concentration in Phase 2 decreased to approximately 33% of that observed in Phase 1. The effluent concentrations of  were negligible throughout the steady-state periods, while the average effluent

were negligible throughout the steady-state periods, while the average effluent  concentration decreased only slightly in Phase 2 as compared to Phase 1. The total inorganic nitrogen (TIN) removal efficiency was calculated for the steady-state periods with values of 62 and 84% for Phases 1 and 2, respectively.

concentration decreased only slightly in Phase 2 as compared to Phase 1. The total inorganic nitrogen (TIN) removal efficiency was calculated for the steady-state periods with values of 62 and 84% for Phases 1 and 2, respectively.

The results indicate that the largest contribution to the increased TIN removal with reduced mixing intensity was the increased removal of  which could be attributed to increase the activity of either AOB or anammox. It was hypothesized that the AOB activity would increase with mixing intensity since it would depend on the availability of both

which could be attributed to increase the activity of either AOB or anammox. It was hypothesized that the AOB activity would increase with mixing intensity since it would depend on the availability of both  and oxygen to the organisms and both of these would increase with improved mass transfer. By contrast, the anammox activity is reduced in the presence of DO and therefore may increase under conditions of reduced mass transfer. It was not possible to confirm these hypotheses with the data obtained from the continuous operation of the SBR, and the subsequently described batch testing and model application were conducted to investigate the impact of mixing on AOB and anammox activity in more depth.

and oxygen to the organisms and both of these would increase with improved mass transfer. By contrast, the anammox activity is reduced in the presence of DO and therefore may increase under conditions of reduced mass transfer. It was not possible to confirm these hypotheses with the data obtained from the continuous operation of the SBR, and the subsequently described batch testing and model application were conducted to investigate the impact of mixing on AOB and anammox activity in more depth.

The activity tests were conducted with the SBR operating in the batch mode and with known initial concentrations of  ,

,  , and

, and  . Each consisted of anoxic and aerobic periods with the DO concentration in the latter period differing between tests. Trends in substrate concentrations with time were employed to determine substrate utilization rates that were subsequently used to estimate the

. Each consisted of anoxic and aerobic periods with the DO concentration in the latter period differing between tests. Trends in substrate concentrations with time were employed to determine substrate utilization rates that were subsequently used to estimate the  and

and  values.

values.

The concentrations of  ,

,  , and

, and  at

at  that were observed in a test that was conducted in Phase 1, when the DO concentration in the aerobic portion of the test was 0.46 mg O2/L, are shown in Figure 2 and are representatives of those obtained under other test conditions. From Figure 2, it can be seen that the concentration of

that were observed in a test that was conducted in Phase 1, when the DO concentration in the aerobic portion of the test was 0.46 mg O2/L, are shown in Figure 2 and are representatives of those obtained under other test conditions. From Figure 2, it can be seen that the concentration of  initially increased and then decreased linearly in both the anoxic and aerobic conditions. The early increase in the

initially increased and then decreased linearly in both the anoxic and aerobic conditions. The early increase in the  concentrations was attributed to the time required to dissolve and mix the dry substrates that were added to the reactor. Only the concentration profiles obtained after 15 min were used for further analysis of conversion rates.

concentrations was attributed to the time required to dissolve and mix the dry substrates that were added to the reactor. Only the concentration profiles obtained after 15 min were used for further analysis of conversion rates.

Nitrogen species concentrations in the activity test at  : (a) anoxic condition and (b) 0.46 mg O2/L.

: (a) anoxic condition and (b) 0.46 mg O2/L.

Nitrogen species concentrations in the activity test at  : (a) anoxic condition and (b) 0.46 mg O2/L.

: (a) anoxic condition and (b) 0.46 mg O2/L.

The trends in substrate responses in the batch tests were consistent with the metabolisms that were anticipated to be active in the different aeration conditions. Under anoxic conditions,  and

and  concentrations decreased and

concentrations decreased and  increased over time. These responses were observed in all of the anoxic tests and were attributed to the activity of anammox organisms. Under aerobic conditions, the

increased over time. These responses were observed in all of the anoxic tests and were attributed to the activity of anammox organisms. Under aerobic conditions, the  concentrations decreased, while

concentrations decreased, while  concentrations increased in all tests. By contrast,

concentrations increased in all tests. By contrast,  concentrations declined with time in tests conducted when the DO was in the range of 0.5 mg/L (as observed in Figure 2) but increased with time in tests with higher DO concentrations. The results obtained under the aerobic conditions were somewhat inconsistent with predictions based on DO half-velocity constants reported in the literature (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016) where values of 0.01 mg O2/L have been reported for anammox organisms. With DO concentrations of 0.5 mg O2/L in the bulk liquid, it was anticipated that

concentrations declined with time in tests conducted when the DO was in the range of 0.5 mg/L (as observed in Figure 2) but increased with time in tests with higher DO concentrations. The results obtained under the aerobic conditions were somewhat inconsistent with predictions based on DO half-velocity constants reported in the literature (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016) where values of 0.01 mg O2/L have been reported for anammox organisms. With DO concentrations of 0.5 mg O2/L in the bulk liquid, it was anticipated that  would not be removed in the system as the anammox activity would be inhibited. The

would not be removed in the system as the anammox activity would be inhibited. The  removal that was observed in the 0.5 mg O2/L aerobic conditions under both mixing conditions suggested the presence of anoxic zones within the granule structures.

removal that was observed in the 0.5 mg O2/L aerobic conditions under both mixing conditions suggested the presence of anoxic zones within the granule structures.

Figure 3 presents the net rates of  ,

,  , and

, and  conversion versus DO concentration that were observed in the batch tests for both phases. These rates were calculated based on the slopes of the nitrogen species concentration responses that were generated in the aerobic batch tests. A positive value for the rate was interpreted to indicate that the production rate of the species was greater than the consumption rate, while a negative value indicated that the production rate was less than the consumption rate.

conversion versus DO concentration that were observed in the batch tests for both phases. These rates were calculated based on the slopes of the nitrogen species concentration responses that were generated in the aerobic batch tests. A positive value for the rate was interpreted to indicate that the production rate of the species was greater than the consumption rate, while a negative value indicated that the production rate was less than the consumption rate.

Estimated nitrogen conversion rates (± std error) versus DO concentrations in activity tests (including anoxic and aerobic tests): (a)  and (b)

and (b)  .

.

Estimated nitrogen conversion rates (± std error) versus DO concentrations in activity tests (including anoxic and aerobic tests): (a)  and (b)

and (b)  .

.

The  ,

,  , and

, and  conversion rates under anoxic conditions at both

conversion rates under anoxic conditions at both  and

and  were similar. The consistency in responses between the different mixing conditions implied that diffusional limitations were not impacting on the anoxic process rates. The lack of apparent diffusional limitations under these conditions suggested that the rates of anammox consumption were being limited by some other factors such as growth processes; therefore, diffusion was less important.

were similar. The consistency in responses between the different mixing conditions implied that diffusional limitations were not impacting on the anoxic process rates. The lack of apparent diffusional limitations under these conditions suggested that the rates of anammox consumption were being limited by some other factors such as growth processes; therefore, diffusion was less important.

As DO concentration increased, the  conversion rates became more negative and subsequently plateaued at elevated DO values (Figure 3). The highest

conversion rates became more negative and subsequently plateaued at elevated DO values (Figure 3). The highest  consumption rates occurred when the DO concentration was the highest as would be expected as the oxygen availability to AOB became non-limiting at high DO values. By contrast, the

consumption rates occurred when the DO concentration was the highest as would be expected as the oxygen availability to AOB became non-limiting at high DO values. By contrast, the  net conversion rates increased and then plateaued as DO increased in the aerobic tests (Figure 3). The results indicate that when the DO concentration was less than or equal to 0.78 mg O2/L at

net conversion rates increased and then plateaued as DO increased in the aerobic tests (Figure 3). The results indicate that when the DO concentration was less than or equal to 0.78 mg O2/L at  or 0.46 mg O2/L at

or 0.46 mg O2/L at  ,

,  was consumed with the rate of consumption greater than the rate of production, and at higher DO concentrations,

was consumed with the rate of consumption greater than the rate of production, and at higher DO concentrations,  was produced with the rate of consumption less than the rate of production. Although the trends in net

was produced with the rate of consumption less than the rate of production. Although the trends in net  conversion rates were similar at

conversion rates were similar at  and

and  , the DO concentrations at which the net

, the DO concentrations at which the net  conversion rate equaled to zero were different. At

conversion rate equaled to zero were different. At  , the DO concentration that the net

, the DO concentration that the net  conversion rate equaled to zero was between 0.78 and 1.2 mg O2/L; whereas at

conversion rate equaled to zero was between 0.78 and 1.2 mg O2/L; whereas at  , this DO concentration was between 0.46 and 0.76 mg O2/L. The different trends in this response as a function of mixing supported the need to further investigate the impact of DO concentration on anammox bacteria by evaluating the observed DO half-velocity constants in the experiments.

, this DO concentration was between 0.46 and 0.76 mg O2/L. The different trends in this response as a function of mixing supported the need to further investigate the impact of DO concentration on anammox bacteria by evaluating the observed DO half-velocity constants in the experiments.

The net  conversion rates were relatively small relative to the other N species, were always positive, and decreased slightly as DO increased. The decrease of

conversion rates were relatively small relative to the other N species, were always positive, and decreased slightly as DO increased. The decrease of  conversion rates was most apparent when the DO concentration was greater than 4.0 mg O2/L as most

conversion rates was most apparent when the DO concentration was greater than 4.0 mg O2/L as most  was oxidized to

was oxidized to  . The decrease in

. The decrease in  conversion rates as DO increased confirmed the low activity of NOB in the system. When DO was lower than 1.0 mg O2/L, some

conversion rates as DO increased confirmed the low activity of NOB in the system. When DO was lower than 1.0 mg O2/L, some  was produced and this was attributed to anammox bacteria; when DO was higher than 4.0 mg O2/L, anammox bacteria stopped producing

was produced and this was attributed to anammox bacteria; when DO was higher than 4.0 mg O2/L, anammox bacteria stopped producing  .

.

The results obtained from the activity testing provided information on the net processes that were active in the tests. However, it was not possible to directly estimate half-velocity coefficients from the data. A model (Ni et al. 2014) that described the active bacterial groups was configured to reflect the batch tests. The model calculates rates of growth and substrate consumption on the basis of bulk liquid substrate concentrations, and the effect of diffusional resistances (external and internal) is embedded in the estimated half-velocity coefficients (extant). The details of the model implementation are described in Supplementary Materials. Default values were assumed for all model parameters (Ni et al. 2014) with the exception of the oxygen half-velocity coefficients for the AOB and anammox species that were estimated by separate multiple response regressions of the data from the two mixing conditions.

The quality of the model fit was assessed by comparing the predicted conversion rates versus the observed rates (Figure 4). Based on the close fit of the data points relative to the perfect fit line and the random distribution of the residuals, it was concluded that the calibrated model successfully described the studied system. Furthermore, the good fit of the model predictions to the observed data for all three nitrogen species over a range of growth conditions indicated that the observed removal rates of the species, relative to each other, were consistent with the theoretical stoichiometric values that were incorporated in the model. The best-fit  values were estimated to be 0.54 ± 0.56 and 0.68 ± 0.34 mg O2/L for the

values were estimated to be 0.54 ± 0.56 and 0.68 ± 0.34 mg O2/L for the  and

and  scenarios, respectively, and were found to be statistically similar (p > 0.05). The values were consistent with the range of values that have been reported in the literature and which vary from 0.18 to 1.16 mg O2/L (Arnaldos et al. 2015; Ma et al. 2016). The best-fit

scenarios, respectively, and were found to be statistically similar (p > 0.05). The values were consistent with the range of values that have been reported in the literature and which vary from 0.18 to 1.16 mg O2/L (Arnaldos et al. 2015; Ma et al. 2016). The best-fit  values were estimated to be 0.55 ± 0.40 and 0.13 ± 0.09 mg O2/L for the

values were estimated to be 0.55 ± 0.40 and 0.13 ± 0.09 mg O2/L for the  and

and  scenarios, respectively, and the former value was determined to be statistically larger than the latter

scenarios, respectively, and the former value was determined to be statistically larger than the latter  . Both values were found to be higher than the literature value of 0.01 mg O2/L (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016).

. Both values were found to be higher than the literature value of 0.01 mg O2/L (Vangsgaard et al. 2013; Ni et al. 2014; Corbalá-Robles et al. 2016).

Estimated versus actual conversion rates in activity tests (including anoxic and aerobic tests): (a)  and (b)

and (b)  .

.

Estimated versus actual conversion rates in activity tests (including anoxic and aerobic tests): (a)  and (b)

and (b)  .

.

The model employed in this study uses the DO concentration in the bulk liquid to describe the exposure of bacteria to DO. It is believed that this was the primary reason that the estimated  values were higher than the literature value, while the

values were higher than the literature value, while the  values were similar to the literature at both mixing intensities. The literature values of

values were similar to the literature at both mixing intensities. The literature values of  and

and  were based on bacteria in flocculant systems with minimal mass transfer limitations (Arnaldos et al. 2015; Picioreanu Pérez & van Loosdrecht 2016; Wu et al. 2017). For a reactor with granules composed of different groups of bacteria, the DO concentration decreases from the bulk liquid to the core of a granule (IWA 2006). Therefore, using the DO concentration values in the bulk liquid resulted in the estimated

were based on bacteria in flocculant systems with minimal mass transfer limitations (Arnaldos et al. 2015; Picioreanu Pérez & van Loosdrecht 2016; Wu et al. 2017). For a reactor with granules composed of different groups of bacteria, the DO concentration decreases from the bulk liquid to the core of a granule (IWA 2006). Therefore, using the DO concentration values in the bulk liquid resulted in the estimated  values being larger than the literature value, because the estimated

values being larger than the literature value, because the estimated  incorporated the effect of all the resistance to DO penetration through the layers surrounding the anammox bacteria core. The similarity in the

incorporated the effect of all the resistance to DO penetration through the layers surrounding the anammox bacteria core. The similarity in the  values in the current study to those in the literature and the lack of the effect of mixing intensities could be attributed to the close proximity of the AOB to the surface of the granules and the absence of a significant mass transfer resistance.

values in the current study to those in the literature and the lack of the effect of mixing intensities could be attributed to the close proximity of the AOB to the surface of the granules and the absence of a significant mass transfer resistance.

The estimated  and

and  values give some insights into the functionality of the different bacterial communities and their abilities to consume substrates in the PN/A process. The TIN removal efficiencies observed in this study indicated that the performance was improved at the

values give some insights into the functionality of the different bacterial communities and their abilities to consume substrates in the PN/A process. The TIN removal efficiencies observed in this study indicated that the performance was improved at the  mixing intensity as compared to that experienced at

mixing intensity as compared to that experienced at  . The results from the batch tests demonstrated that the

. The results from the batch tests demonstrated that the  increased as the mixing speed decreased in Phase 2. Thus, the anammox bacteria experienced less DO inhibition at

increased as the mixing speed decreased in Phase 2. Thus, the anammox bacteria experienced less DO inhibition at  as compared to

as compared to  ; thereby, the TIN removal efficiency was higher at

; thereby, the TIN removal efficiency was higher at  . The results of this study provide process engineers with quantitative information that can be employed to establish mixing conditions for granular PN/A processes that could increase TIN removal performance. Furthermore, the

. The results of this study provide process engineers with quantitative information that can be employed to establish mixing conditions for granular PN/A processes that could increase TIN removal performance. Furthermore, the  and

and  values developed in this study can be employed to improve models of PN/A processes that quantitatively reflect the impact of mixing conditions on biological process rates.

values developed in this study can be employed to improve models of PN/A processes that quantitatively reflect the impact of mixing conditions on biological process rates.

CONCLUSIONS

In this study, the effects of mixing intensity on a PN/A process were characterized. The steady-state operation was achieved after 83 days of operation at 15 s−1 with an average total nitrogen removal of 62%, while after 22 days of operation at 5.3 s−1 with an average of total nitrogen removal of 84%. Activity test results showed that as DO increased at both G values, the rates of ammonium consumption increased and then plateaued; the rate of nitrite production increased and then plateaued; and the rate of nitrate production had no apparent change. The rates of ammonium and nitrite changes plateaued at higher DO values for G values of 5.3 s−1 when compared to 15 s−1. A bioprocess model was used to estimate the values of  and

and  from the activity test results. The estimated DO half-velocity constants for AOB were 0.54 mg O2/L at 5.3 s−1 to 0.68 mg O2/L at 15 s−1 and were not statistically different. The estimated DO half-velocity constants for anammox bacteria were determined to be 0.55 mg O2/L at 5.3 s−1 and 0.13 mg O2/L at 15 s−1 which were found to be statistically different. The results of this study provide insights that can be employed to simulate AOB and anammox bacteria growth using the DO concentration in the bulk liquid.

from the activity test results. The estimated DO half-velocity constants for AOB were 0.54 mg O2/L at 5.3 s−1 to 0.68 mg O2/L at 15 s−1 and were not statistically different. The estimated DO half-velocity constants for anammox bacteria were determined to be 0.55 mg O2/L at 5.3 s−1 and 0.13 mg O2/L at 15 s−1 which were found to be statistically different. The results of this study provide insights that can be employed to simulate AOB and anammox bacteria growth using the DO concentration in the bulk liquid.

ACKNOWLEDGEMENTS

All authors thank the Natural Sciences and Engineering Research Council of Canada (NSERC grant no. 50503) for the funding of this research.

SUPPLEMENTARY MATERIAL

The Supplementary Material for this paper is available online at https://dx.doi.org/10.2166/wqrj.2019.009.

%20cropped.png?versionId=5955)